Heat exchangers are essential components in HVAC systems that distribute heat from one fluid (liquid or gas) to another without allowing the fluids to mix. Heat exchangers work by facilitating the transfer of heat between two fluids, often with the help of a conductive material like metal. They last about 15 years.

In gas furnaces, heat exchangers are responsible for transferring the heat generated by the burning of natural gas or propane to the air that circulates through your home. Some furnaces even contain two heat exchangers. The heated air is then distributed via ductwork to keep your living spaces comfortable.

Heat exchangers also play a vital role in enhancing energy efficiency by recovering heat from exhaust air or fluid and transferring it to incoming fresh air or fluid, reducing the workload on your system.

Throughout this article, we will explore what heat exchangers do in an hvac, the various types of heat exchangers, and how to use a heat exchanger for efficient heating and cooling in your home.

Contents

Types of Heat Exchangers in HVAC System

1. Air to Air Heat Exchangers

Source: Industrial Quick Search

Air to air heat exchangers consist of two separate air streams that flow through the exchanger, allowing heat transfer between them without mixing the air. This kind of heat exchanger is commonly found in ventilation systems, where it recovers heat from the exhaust air and uses it to precondition incoming fresh air. By doing so, air to air heat exchangers can significantly improve energy efficiency, and enhance indoor air quality.

One disadvantage of air to air heat exchangers is that their effectiveness can be reduced by fouling, which occurs when dirt, dust, or other contaminants accumulate on the heat transfer surfaces.

2. Water to Air Heat Exchangers

Water to air heat exchangers distribute heat between water and air, making them ideal for HVAC systems that use a water source, such as a boiler or chiller, to provide or absorb heat.

These heat exchangers typically consist of a series of coils or tubes through which water flows, while air passes over the exterior surfaces to cool or heat the air effectively. The design allows for efficient heat transfer between the two fluids.

Water to air heat exchangers offer several advantages, including flexible installation options and suitability for various HVAC applications. However, they also have some potential drawbacks, such as the risk of water leaks and the need for good water quality to prevent scaling and corrosion, which can reduce the heat exchanger’s efficiency and lifespan.

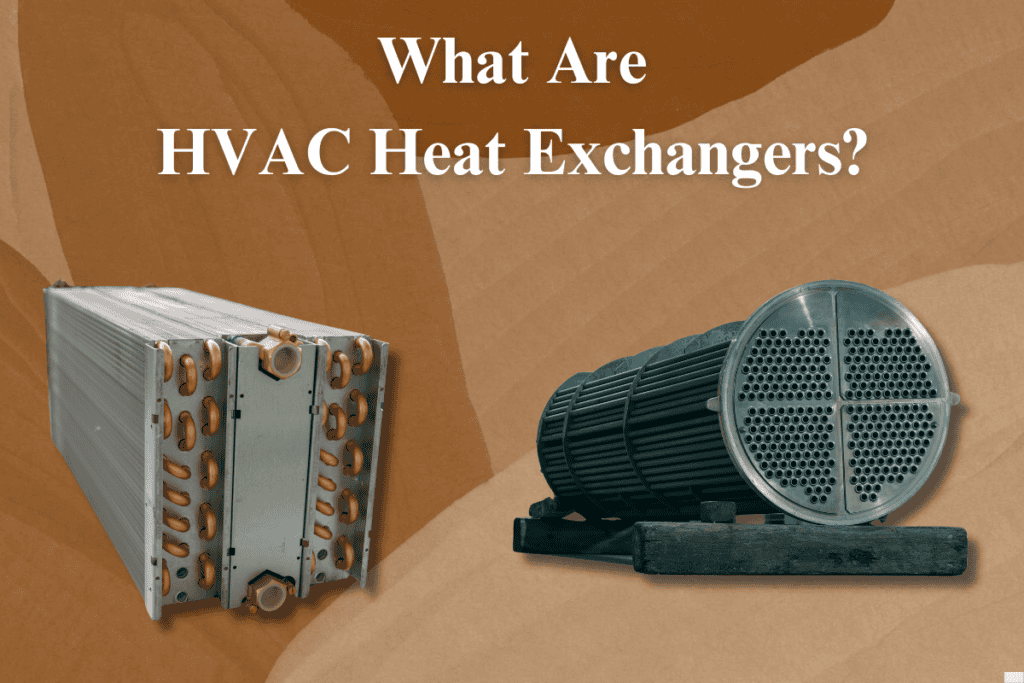

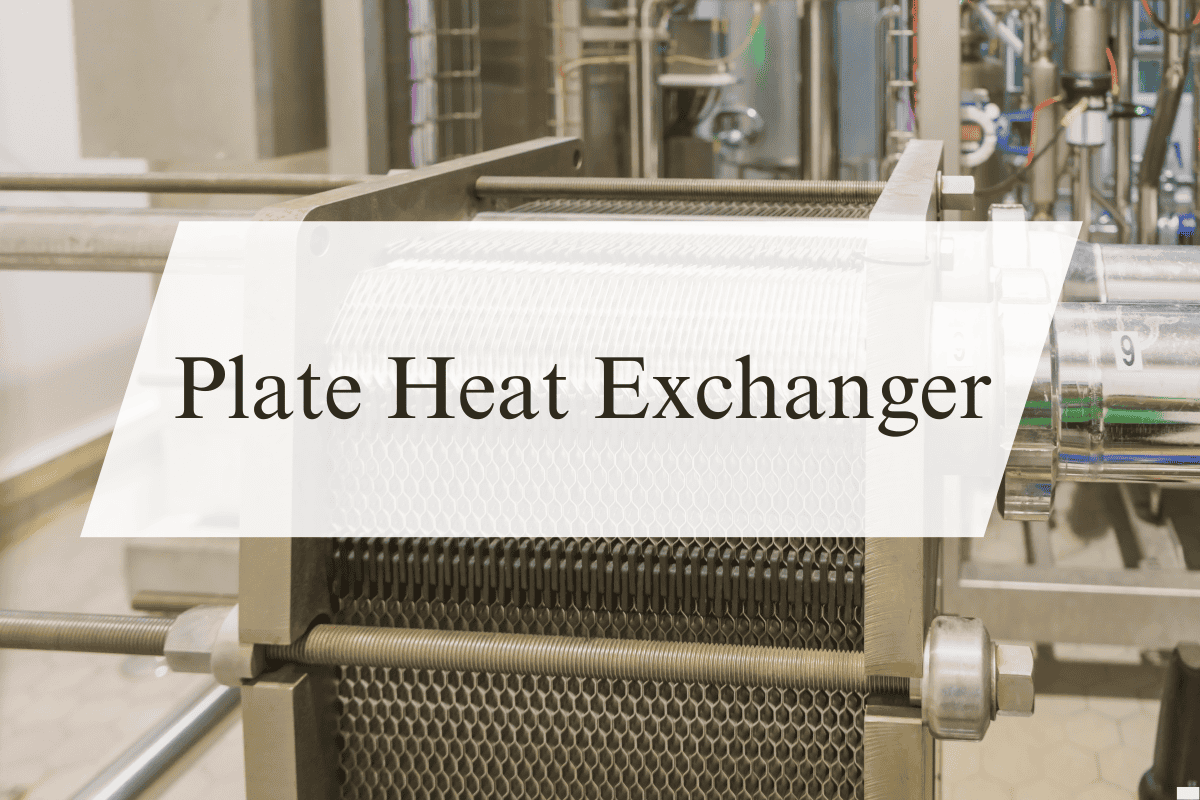

3. Plate Heat Exchangers

Plate heat exchangers use thin metal plates stacked together to transfer heat between two fluids. The fluids flow through alternating channels between the plates, allowing for efficient heat exchange, making these heat exchangers used in hvac systems highly effective.

The main advantage of plate heat exchangers is their high efficiency, which is due to the large surface area provided by the numerous plates. They also have a compact design, making them suitable for installations with limited space.

However, plate heat exchangers can be prone to fouling, especially in applications with contaminated fluids.

4. Shell and Tube Heat Exchangers

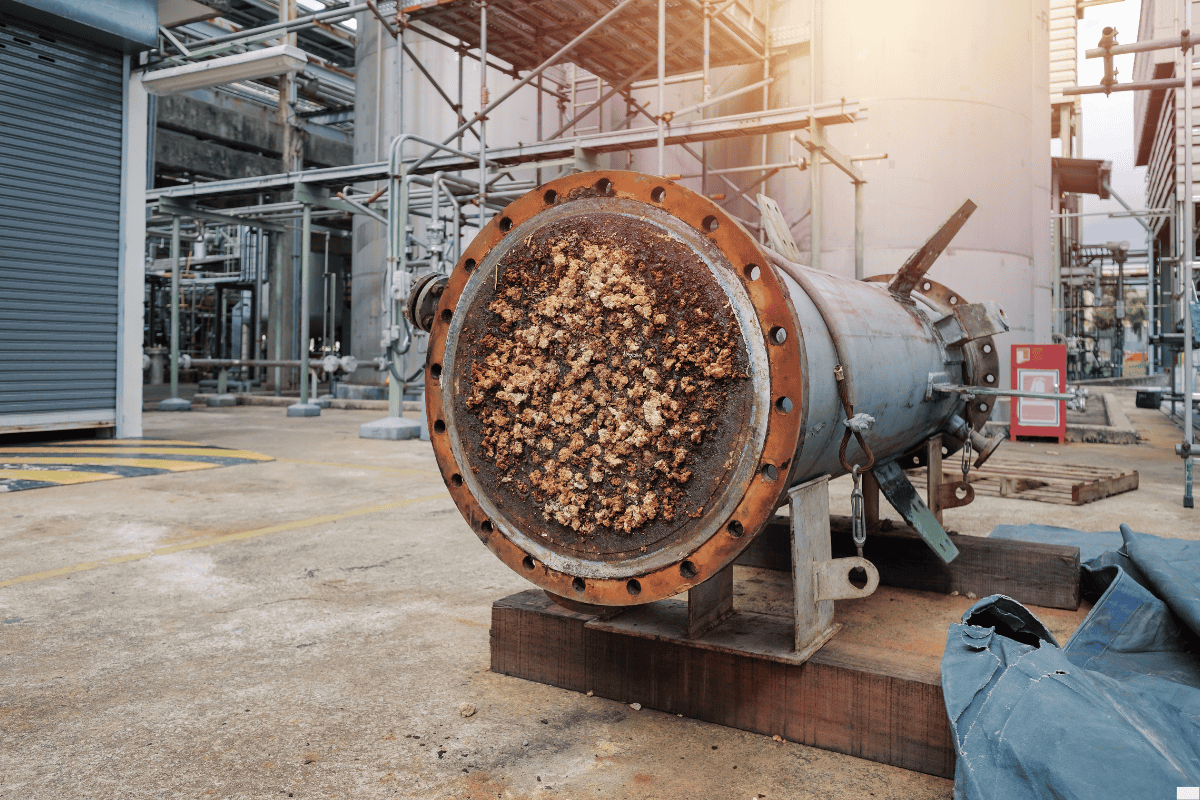

Shell and tube heat exchangers consist of a series of tubes enclosed within a shell. One fluid flows through the tubes, while another fluid flows over the tubes within the shell, allowing for heat transfer between the two fluids. These heat exchangers are commonly used in larger systems, including industrial applications.

The main advantages of shell and tube heat exchangers are their robustness and durability. They are suitable for high pressure and high temperature applications and offer versatility in design to meet specific needs.

However, shell and tube heat exchangers are generally larger and heavier than other kinds of heat exchangers. They are also more complex to clean and maintain, which can lead to higher operational costs.

How Heat Exchangers Work?

Heat exchangers work by conveying heat from a warmer substance to a cooler one, allowing heat to move between two fluids or between a fluid and air without mixing them.

The most important factor when choosing a material for heat exchangers is thermal conductivity, as they work on the principle of heat transfer. Materials with high thermal conductivity, such as copper, aluminum, and brass, are often used in heat exchanger construction for efficient heat transfer.

There are three main mechanisms by which heat transfer occurs in heat exchangers:

1. Conduction: Heat is transferred through a solid barrier, like metal plates or tubes, from the hotter fluid to the cooler fluid.

2. Convection: Heat is transferred within the fluids themselves as they flow over or through the heat exchanger surfaces.

3. Radiation: Although less significant in most HVAC applications, heat can also be transferred through electromagnetic waves.

In a typical heat exchanger, two fluid streams (e.g., air, water, or refrigerant) flow through separate pathways. As the fluids pass through the exchanger, one stream loses heat and cools down, while the other gains heat and warms up. The direction of the fluid flow can affect the efficiency of the heat transfer:

Counterflow arrangements: Fluids flow in opposite directions, maximizing the temperature gradient and heat transfer efficiency.

Parallel flow arrangements: Fluids flow in the same direction, which is less efficient due to a smaller temperature gradient.

To maximize heat transfer, heat exchanger surfaces are designed to increase surface area while minimizing resistance to fluid flow. Common designs include plates, fins, and tubes, which allow for greater contact between the fluids and the heat transfer surfaces.

Applications of Heat Exchangers in HVAC

1. Heating Systems

In furnaces, heat exchangers are responsible for transferring heat from the combustion gases to the air that circulates throughout the building. The heat exchanger is an essential component of your furnace, as it allows the heat from the burning fuel to warm the air without mixing the combustion gases with the indoor air. This process provides efficient and safe space heating by furnaces.

Similarly, in boilers, heat exchangers distribute heat from the combustion process to water. The heated water or steam is then distributed through pipes to radiators or other heat emitters, providing warmth to the building.

2. Cooling Systems

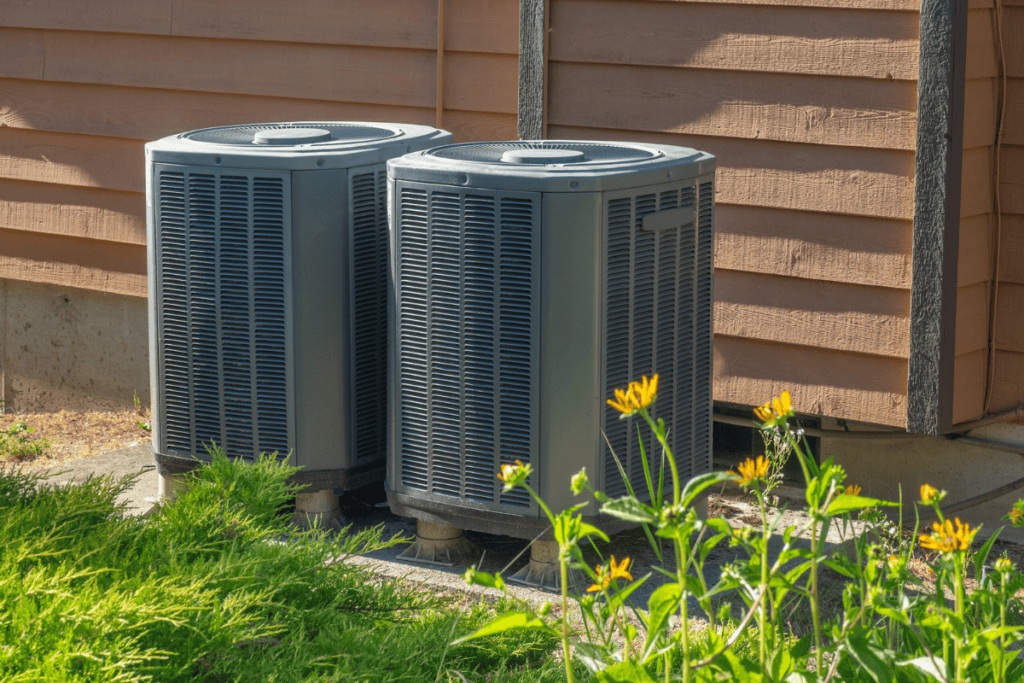

Air conditioners employ heat exchangers to remove heat from the air inside your home and transfer it to the refrigerant. The heat exchanger in your air conditioning system is typically called an evaporator coil.

As warm air travels over the cool evaporator coil, the refrigerant absorbs the heat, cooling the air in the process. The refrigerant then carries this heat to another heat exchanger, known as the condenser coil, where it is released into the outdoor environment.

In chillers, heat exchangers are used to transfer heat from the building’s water supply to the refrigerant. The chilled water is then circulated through the building to provide cooling via fan tubing units or other cooling devices.

3. Ventilation Systems

Energy Recovery Ventilators (ERVs) and Heat Recovery Ventilators (HRVs) are ventilation systems that use heat exchangers to improve energy efficiency and maintain indoor air quality.

In an ERV, the heat exchanger transfers both heat and moisture between the air streams. This process helps to precondition the incoming air, reducing the load on the heating and cooling systems while maintaining a comfortable humidity level.

HRVs, on the other hand, focus solely on heat transfer. The heat exchanger in an HRV recovers heat from the exhaust air and transfers it to the incoming fresh air during the heating season. In the cooling season, the process is reversed, with the heat exchanger cooling the incoming air by emitting heat to the exhaust air.

Want Help With Your Heat Exchanger? Call HVAC Angel

At HVAC Angel, we understand the role heat exchangers play in keeping your home comfortable and your HVAC system running efficiently. We pride ourselves on providing top-notch services so that your heat exchangers are functioning at their best.

Our team of highly skilled and experienced technicians is well-versed in servicing, repairing, and replacing heat exchangers in various HVAC systems. We use state-of-the-art equipment and techniques to diagnose and resolve any issues with your heat exchangers promptly and effectively.

When you choose HVAC Angel, you can trust that you’re getting the best service possible. We prioritize customer satisfaction and our technicians are friendly, professional, and committed to delivering exceptional results.

Don’t let a malfunctioning heat exchanger compromise your comfort or energy efficiency. Contact HVAC Angel today to schedule a service appointment. Experience the difference of working with the best in the business – call HVAC Angel now!

Frequently Asked Questions

1. Are heat exchangers 100% efficient?

No, heat exchangers are not 100% efficient. The efficiency of a heat exchanger depends on various factors, such as the design, materials used, and the temperature difference between the fluids. Most heat exchangers have an efficiency between 60% and 90%.

2. Which heat exchanger is better?

The best heat exchanger for your HVAC system depends on your specific needs and application. Factors to consider include the type of fluids, temperature range, pressure, and space constraints. Consult with an experienced HVAC technician to determine the most suitable heat exchanger for your system.

3. How to size heat exchangers?

Sizing a heat exchanger involves calculating the required heat transfer rate, considering factors such as fluid properties, flow rates, and temperature differences. Proper sizing provides good performance and efficiency.

![9 Reasons That Causes an AC Unit to Freeze Up: [Troubleshooting Guide]](https://hvacangel.com/wp-content/uploads/2024/05/what-causes-a-ac-unit-to-freeze-up-1024x683.png)