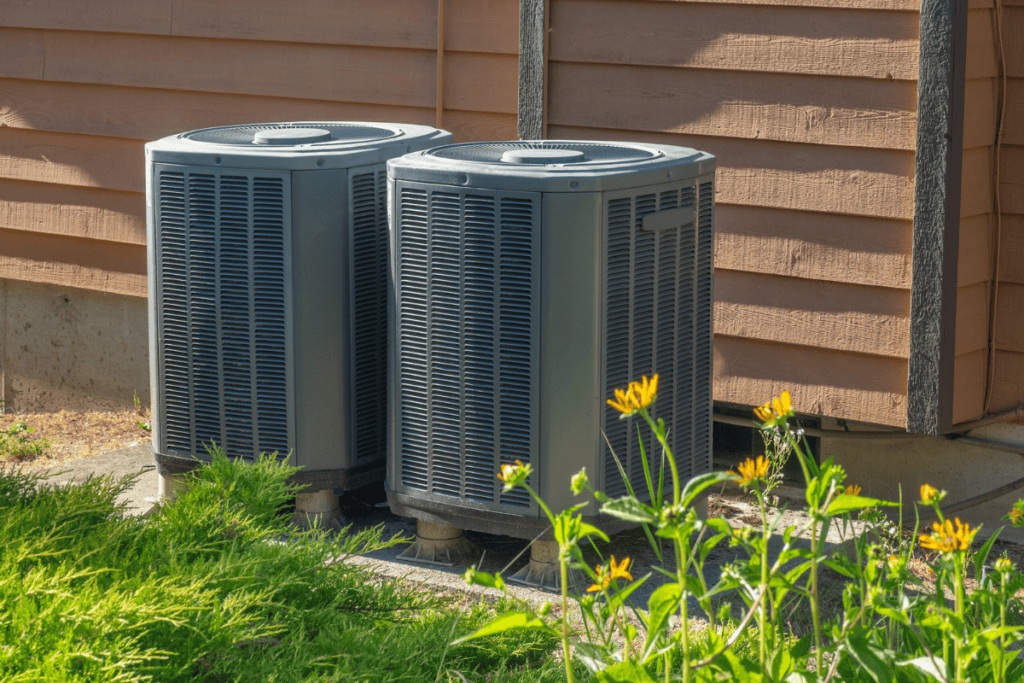

Your AC system is the unsung hero of your home, working tirelessly to keep you cool and comfortable during the hot summer months. But have you ever wondered what goes on behind the scenes? At the heart of your AC lies a delicate balance of pressure, with the compressor, condenser, evaporator, and refrigerant all working together in harmony.

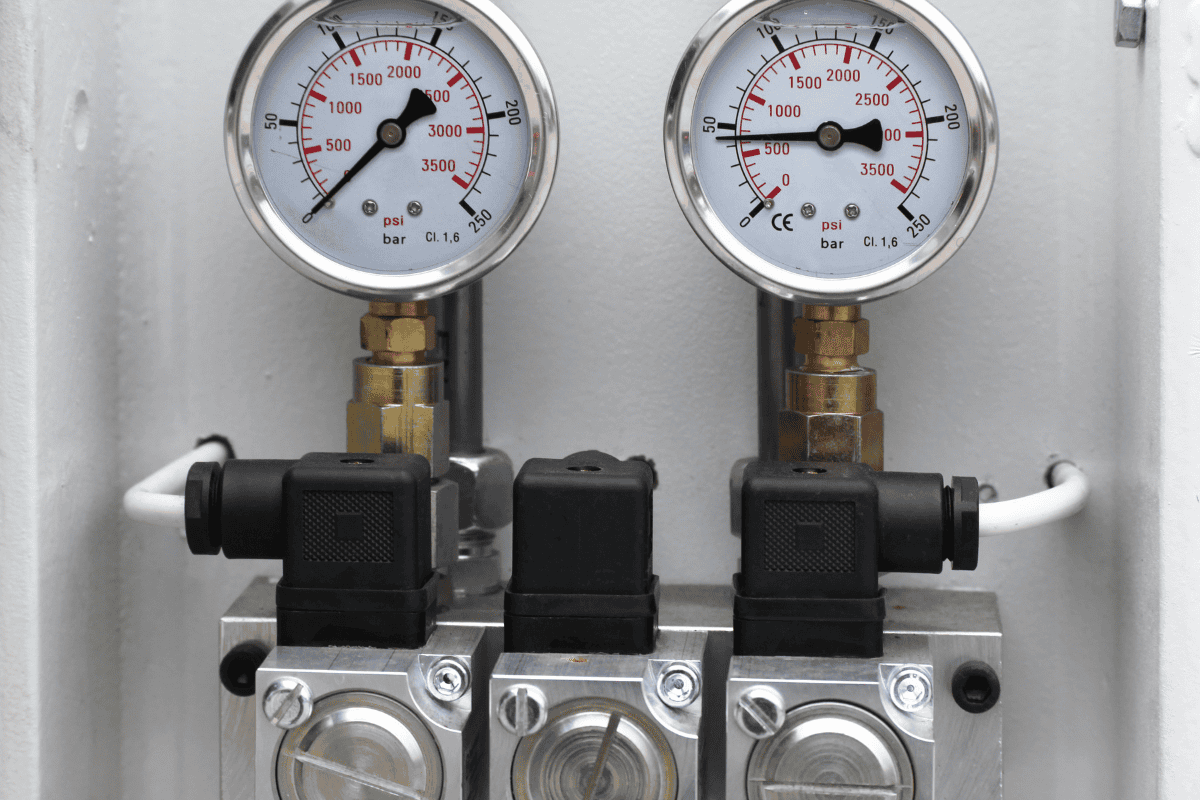

When your system is running smoothly, you should see around 150 PSI on the high side and 30 PSI on the low side. But what happens when these pressure readings start to climb? High pressure in your system can be a real headache, leading to reduced efficiency, increased energy consumption, and even damage to your compressor.

Keeping your system in top shape is crucial for maintaining a comfortable home environment. Understanding the causes of high pressure in your AC and knowing how to address them can save you from costly repairs so that your system runs efficiently.

This guide is designed to help you understand the most common culprits behind high pressure in your system and provide you with the solutions you need to get your AC back on track. From a clogged condenser coil to an overcharged system, we’ll walk you through the issues and explain how to fix them.

Contents

What Causes High Pressure in AC Systems?

1. Refrigerant Overcharge

Refrigerant overcharge occurs when excessive refrigerant is added to the AC system, surpassing the manufacturer’s recommended levels. This excess refrigerant increases the pressure within the system, putting additional strain on the compressor. As a result, the compressor may experience potential damage, reduced efficiency, and increased energy consumption. Overcharging can also lead to other issues, such as reduced cooling capacity and improper system operation.

2. Restricted Airflow

Restricted airflow is another common factor that contributes to high pressure in systems. When the airflow through the condenser is impeded, heat cannot be effectively dissipated from the system. This can be caused by various issues, such as dirty condenser coils, clogged air filters, or blocked vents.

As a result, heat accumulates within the system, causing the refrigerant temperature and pressure to rise. This increased pressure puts additional stress on the compressor and other components, leading to reduced efficiency and potential damage.

3. Malfunctioning Components

Malfunctioning components within the system can also contribute to high pressure. One such component is the condenser fan, which plays a crucial role in dissipating heat from the condenser coils. If the condenser fan fails or operates improperly, it prevents adequate heat dissipation, causing the refrigerant pressure to increase.

Another component that can cause high pressure is a blocked expansion valve or metering device. It regulates the flow of refrigerant into the evaporator coil. If the valve becomes clogged or malfunctions, it restricts refrigerant flow, leading to increased pressure within the system.

Effects of High Pressure on AC Systems

1. Damage to Components

High pressure in the system can cause significant damage to various components, particularly the compressor. The compressor is the heart of the AC system, responsible for circulating refrigerant and maintaining proper pressure levels.

When subjected to excessive pressure, the compressor experiences increased stress and wear, which can lead to mechanical failure or premature deterioration.

Additionally, high pressure increases the risk of refrigerant leaks, which can further damage other components and compromise the overall cooling capacity of the system.

2. Reduced Efficiency

High pressure adversely affects the efficiency of a system. When the system operates under excessive pressure, it has to work harder to maintain the desired temperature levels. This increased workload results in decreased cooling performance and increased energy consumption.

The system may struggle to effectively cool the space, leading to uneven temperature distribution and reduced comfort. Moreover, the increased energy consumption translates to higher electricity bills, as the system requires more power to operate under high-pressure conditions.

3. Safety Concerns

High pressure in a system poses safety risks to both the equipment and the occupants of the building. In extreme cases, excessive pressure can cause components, such as the compressor or refrigerant lines, to rupture or explode. This can result in serious injury to anyone in close proximity to the system.

Additionally, high pressure increases the likelihood of refrigerant leaks. Some refrigerants, if released into the environment, can be harmful to human health and contribute to environmental issues like ozone depletion and global warming.

4. Shortened Lifespan

Prolonged exposure to high pressure can significantly reduce the lifespan of components. The increased stress and strain on the compressor, condenser coils, and other parts accelerate wear and tear, leading to premature failure.

Regular exposure to high pressure also compromises the overall durability and reliability of the system, reducing its expected service life.

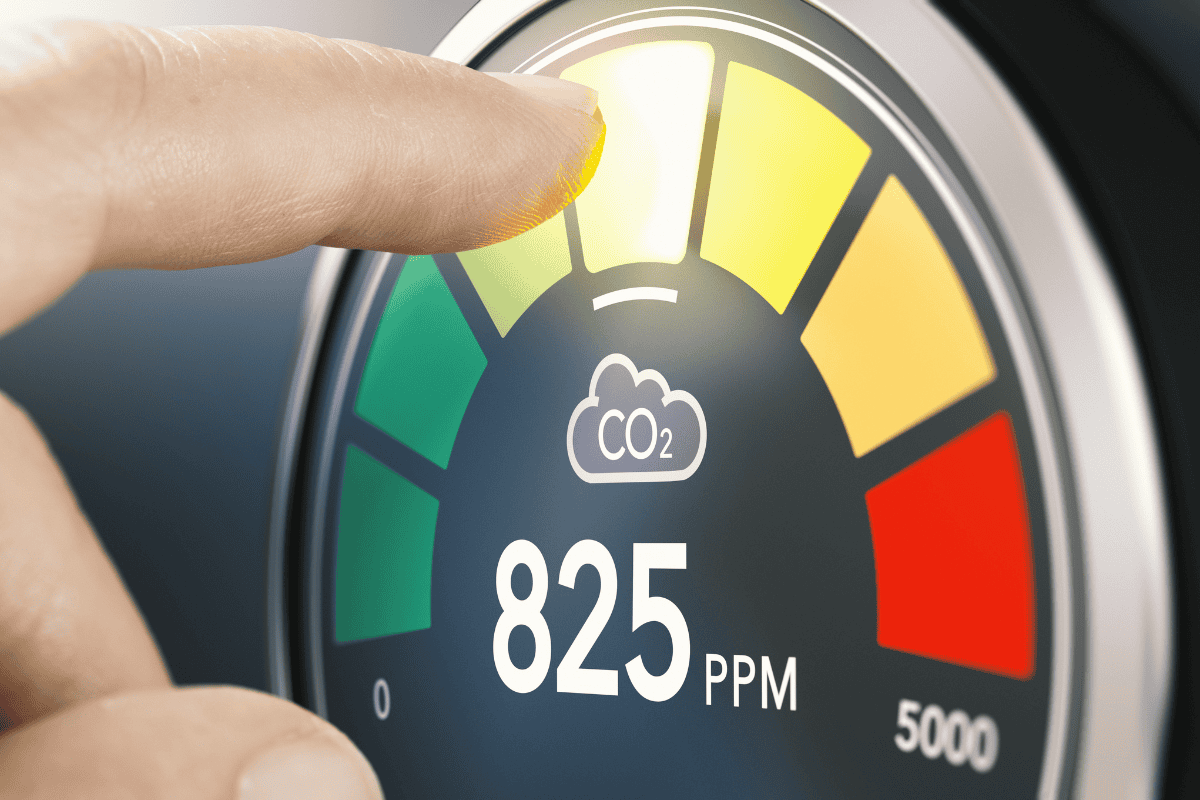

5. Impaired Indoor Air Quality

High pressure in your system can negatively impact indoor air quality. When the system is unable to operate efficiently due to high pressure, it may struggle to effectively remove moisture from the air. This can lead to increased humidity levels, creating an environment conducive to the growth of mold, mildew, and other allergens.

Additionally, high pressure can hinder the system’s ability to properly filter and circulate air, allowing pollutants, dust, and other contaminants to accumulate and recirculate within the indoor space. As a result, occupants may experience respiratory issues, allergic reactions, and other health problems.

How to Diagnose High Pressure Issues

1. Pressure Gauge Readings

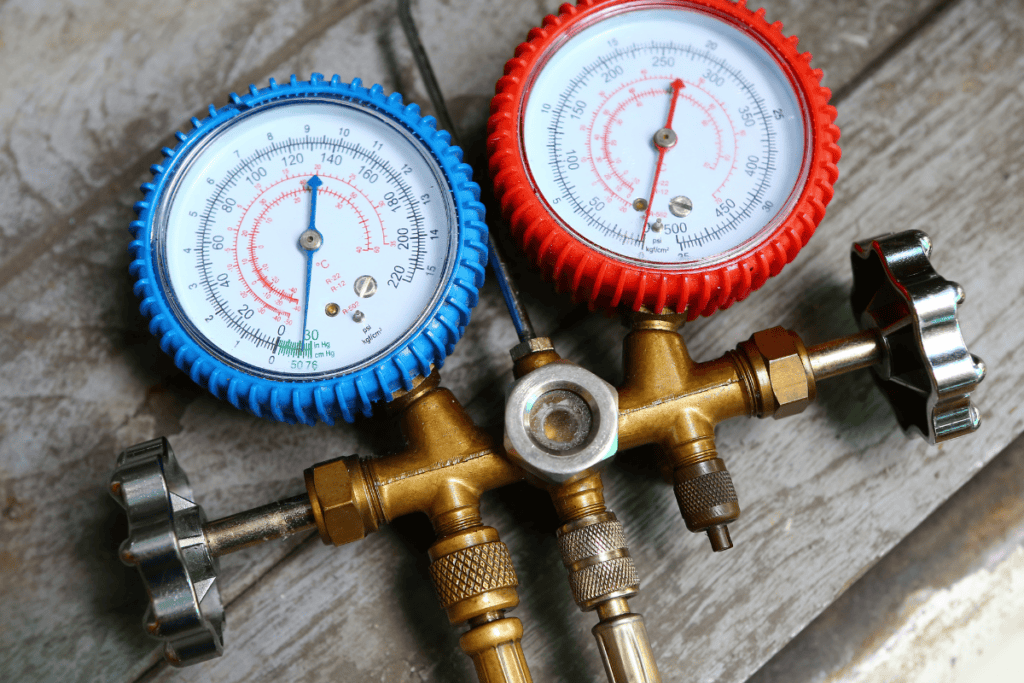

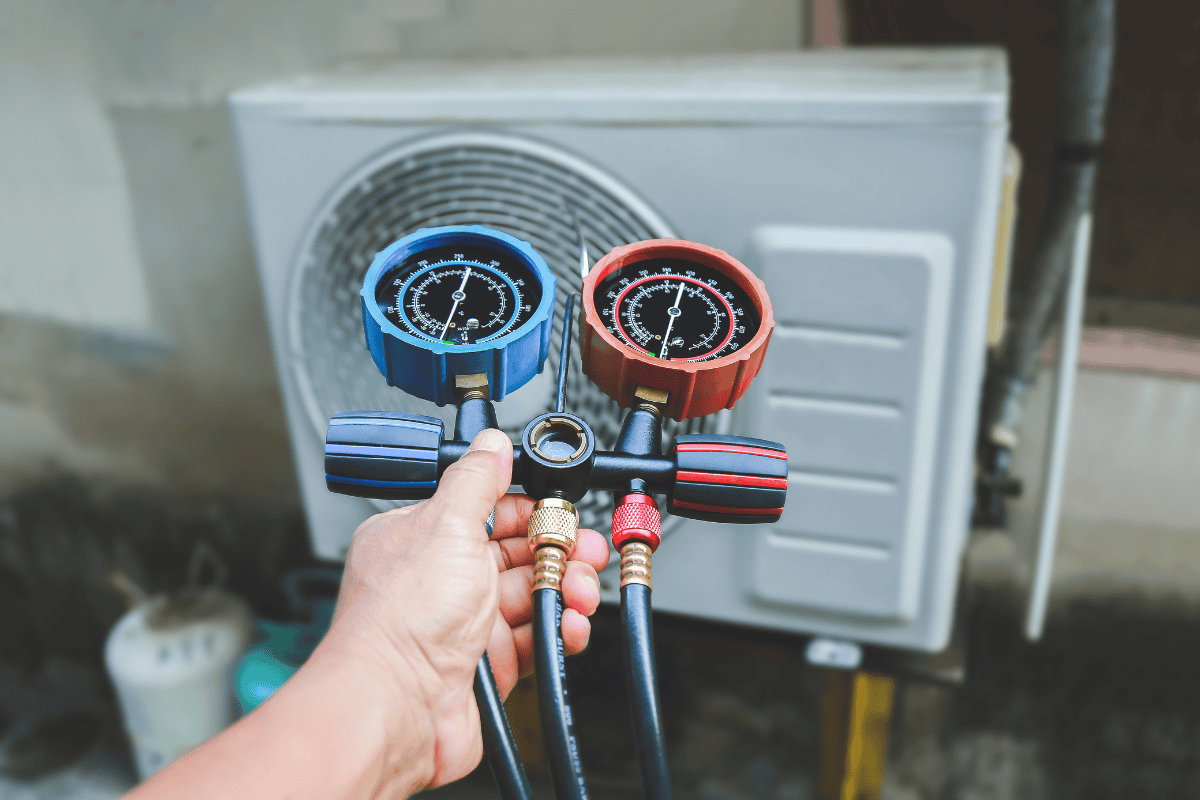

Pressure gauge readings are essential tools to diagnose high pressure issues in air conditioning systems. By measuring the high side pressure and low side pressure, technicians can identify abnormal conditions that may indicate problems like overcharged AC, blockages, or component malfunctions.

2. Visual Inspection

Visual inspection is an important step in diagnosing high pressure problems in an air conditioner. Carefully examining various components of the cooling system, looking for visible signs of issues that can cause high pressure.

This includes checking for blocked air filters, which can restrict airflow and lead to increased head pressure. Inspect the condenser coil for dirt, debris, or bent fins that may hinder heat dissipation and contribute to high pressure.

Other components, such as the fan clutch, fan blades, and refrigerant lines, are visually assessed for damage or obstructions that could impede proper system operation and result in higher pressure readings.

3. System Testing

To further investigate high pressure issues, HVAC technicians perform comprehensive system testing. This involves using specialized tools and techniques to evaluate the performance of the air conditioning system and identify the root cause of the high pressure. One common test is checking the coolant charge using a manifold gauge set.

By measuring the pressure on the high side and low side of the system, technicians can determine if the AC is overcharged or undercharged with coolant, both of which can lead to high pressure problems.

Another important test is measuring the temperature differential across the condenser coil. If the temperature difference is higher than expected, it indicates that the coil is not effectively dissipating heat, possibly due to restrictions in flow of air or a malfunctioning fan.

Technicians may also use infrared thermometers to check for hot spots or uneven cooling, which can signify a blockage or component failure contributing to high pressure.

Preventive Measures and Solutions

1. Regular Maintenance

Regular maintenance is the key that prevents from rising the pressure too high. HVAC professionals recommend scheduling annual maintenance visits to keep the system running efficiently and avoid potential problems. During these visits, technicians perform essential tasks such as cleaning the condenser coil, replacing air filters, and checking refrigerant levels.

Removing dirt and debris from the coil ensures proper heat dissipation and prevents high pressure caused by restricted airflow. Regularly replacing air filters maintains adequate airflow and reduces the strain on the system, helping to prevent high pressure conditions.

2. Proper Refrigerant Charging

Proper coolant charging is crucial for maintaining optimal pressure levels in an air conditioner. Overcharging the system with too much refrigerant can lead to high head pressure, while undercharging can result in insufficient cooling capacity and increased compressor wear.

3. Component Inspection and Repair

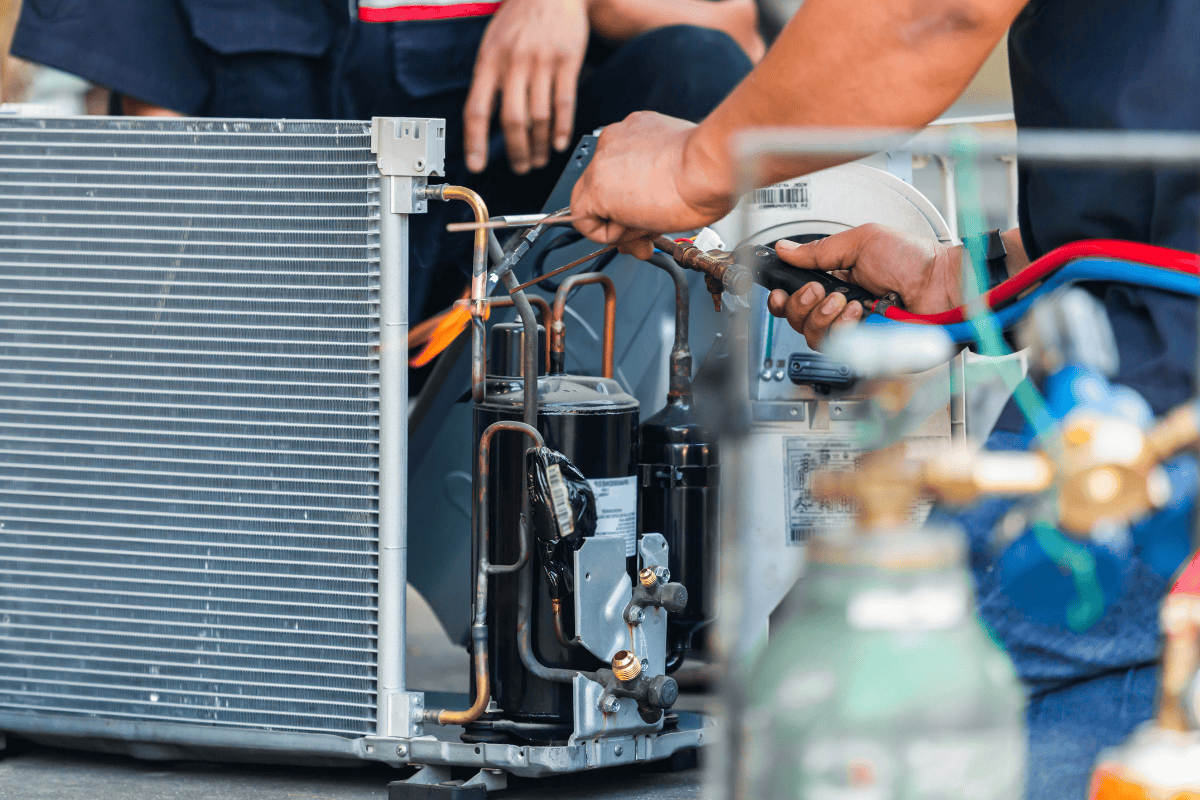

Regular inspection and timely repair of air conditioning components can help prevent high pressure issues from developing. During maintenance visits or when troubleshooting high pressure problems, technicians carefully examine critical components such as the compressor, expansion valve, and coolant lines. They look for signs of wear, damage, or malfunction that could contribute to high pressure.

If any components are found to be faulty, such as a stuck expansion valve or a damaged compressor, technicians recommend prompt repair or replacement to restore proper system operation and avoid further high pressure issues.

Maintain Proper AC Pressure With HVAC Angel

Maintaining proper pressure in your air conditioning system is crucial for optimal performance, energy efficiency, and the longevity of your AC unit. At HVAC Angel, our team of experienced technicians understands the importance of accurate pressure diagnosis and effective solutions to keep your AC running smoothly.

We specialize in identifying and resolving high pressure issues in air conditioners. Our technicians are trained to use advanced tools, such as pressure gauges and manifold sets, to measure the pressure of the high side and low side of your system.

By analyzing these readings, we can pinpoint the causes of high pressure, whether it’s an overcharged AC, restricted flow of air, or a malfunctioning component like a faulty metering device or compressor.

With our commitment to quality service and customer satisfaction, HVAC Angel is your reliable partner in maintaining proper AC pressure, maintaining a cool, comfortable home, and addressing common causes like moisture in the system or a malfunctioning ac low pressure sensor.

Frequently Asked Questions

1. What is normal pressure in 1.5 ton AC?

In a properly functioning 1.5 ton AC unit, the normal high side pressure should be around 150-250 psig, while the low side pressure should be between 30-45 psig. However, these values may vary depending on factors such as outdoor temperature and the specific coolant used.

2. What happens if your AC has too much pressure?

If your AC has too much pressure, it can lead to various issues such as reduced cooling capacity, increased energy consumption, and strain on the compressor. High pressure can cause the compressor to overheat, potentially leading to system failure and costly repairs.

3. What are the symptoms of overcharged AC?

Common symptoms of an overcharged AC include high head pressure, reduced cooling performance, and the compressor shutting off frequently due to the high pressure switch being triggered. You may also notice warm air coming from the vents or frost formation on the evaporator coil.

4. Will AC work if overcharged?

An overcharged AC may still operate, but it will not function efficiently. The excess coolant in the system can cause high pressure, leading to reduced cooling capacity, increased energy consumption, and potential damage to the compressor and other components.

![9 Reasons That Causes an AC Unit to Freeze Up: [Troubleshooting Guide]](https://hvacangel.com/wp-content/uploads/2024/05/what-causes-a-ac-unit-to-freeze-up-1024x683.png)