Static pressure in HVAC systems is a concept that homeowners should understand for optimal performance and efficiency of their heating and cooling equipment. It refers to the resistance encountered by air as it flows through the ductwork of the system. Static pressure is typically measured in units such as inches of water column (in. w.c.) or Pascals (Pa).

Maintaining the right level of static pressure is essential for your system to function properly. High static pressure can lead to reduced airflow, causing your air conditioner or furnace to work harder and consume more energy, resulting in higher utility bills and equipment failure.

On the other hand, low static pressure may indicate leaks in the ductwork or an undersized system, leading to inadequate heating or cooling and poor air quality.

In this article, we will explore in depth the concept of static pressure, discussing its importance, the factors that influence it, and how our technicians measure and optimize static pressure so that your heating and cooling system operates at peak performance.

Contents

Types of Static Pressure In HVAC System

1. Total Static Pressure

Total static pressure is a critical aspect of HVAC systems, as it represents the overall resistance to airflow within the ductwork. It is the sum of both static pressure and velocity pressure, providing a comprehensive measure of the energy required to move air through the system.

Maintaining the right amount of total static pressure is essential for good performance and efficiency of your heating and cooling equipment.

2. External Static Pressure

External static pressure represents the resistance encountered by air as it moves through the ductwork and various components, such as filters, coils, dampers, and grilles. Maintaining the ideal external static pressure is essential for efficient airflow and preventing issues like reduced system performance and increased energy consumption.

3. Internal Static Pressure

Internal static pressure plays a vital role in maintaining efficient airflow distribution within the ductwork of your system. It represents the pressure drop caused by friction as air moves along the walls of the ducts.

What Influences Static Pressure?

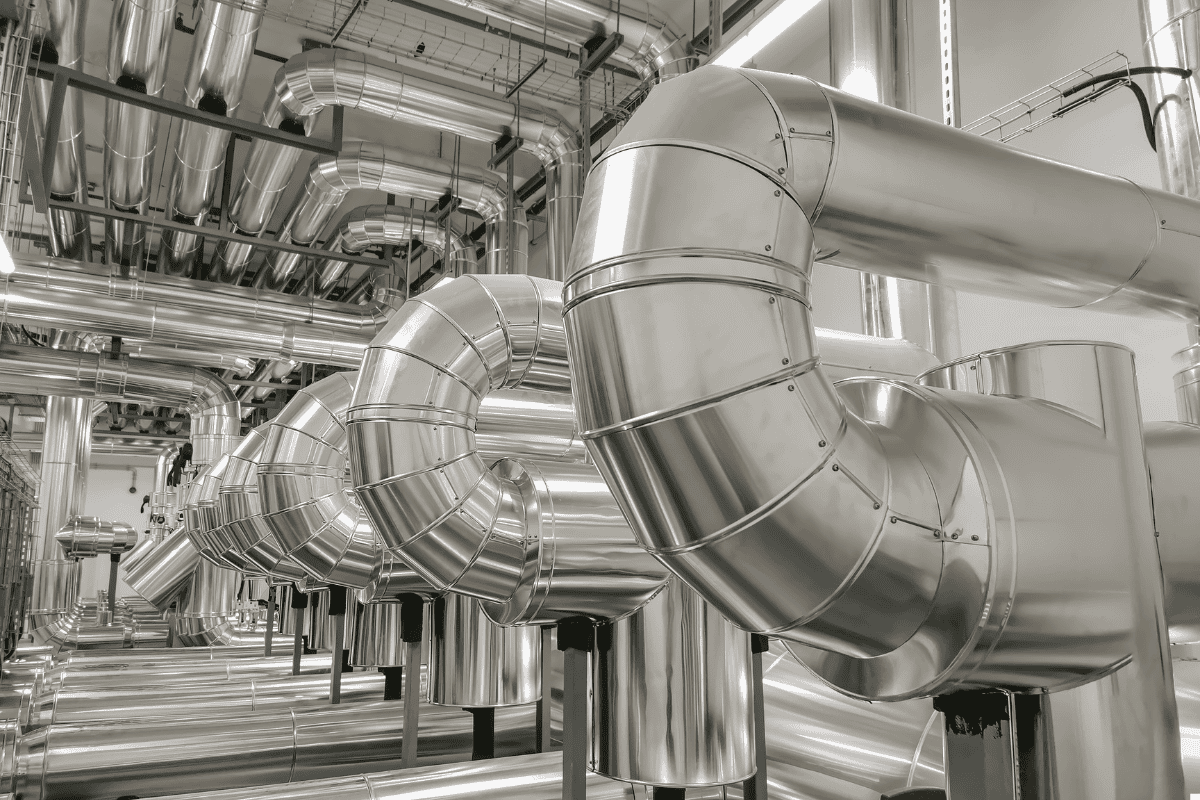

1. Duct Design

Proper duct design is important for good system performance, reducing energy consumption, and preventing issues like hot and cold spots in your home. The size and shape of the ducts directly impact the resistance to airflow, with smaller or irregularly shaped ducts causing higher pressure drops due to increased friction between the air and the duct walls.

Designing duct systems with shorter, straighter runs helps minimize static pressure and maintain efficient airflow.

The material used in duct construction also influences static pressure. Smooth, noncorrosive materials like galvanized steel or aluminum offer lower resistance to airflow compared to rougher materials like fiberglass or flexible ducts.

2. Airflow Volume

Airflow volume is another factor that affects static pressure. Inadequate airflow can lead to poor indoor air quality, reduced comfort levels, and increased energy bills. On the other hand, excessive airflow can cause noise, drafts, and unnecessary strain on your equipment. Striking the right balance in airflow volume is key to optimizing static pressure and overall system performance.

3. Air Filter Condition

Air filters play a vital role in maintaining indoor atmospheric quality and protecting your equipment from dust, debris, and other contaminants. Dirty filter leads to the growth of mold and mildew, causing allergies.

However, as filters accumulate dirt and become clogged over time, they can significantly impact static pressure within the system. Cogged or dirty filters restrict airflow, leading to higher static pressure and reduced system efficiency.

4. Air Handler Condition

The air handler, which includes the fan motor and blades, is responsible for circulating conditioned air throughout your home. The condition of the air handler directly impacts static pressure within the system.

A malfunctioning or improperly sized fan can result in inadequate airflow and increased static pressure, leading to reduced system performance and potential equipment damage.

5. Damper Position

Dampers are mechanical devices used to control airflow within the duct system. The position of these dampers can significantly impact static pressure, as improperly adjusted or closed dampers can cause pressure imbalances and increase resistance to airflow in certain areas of the system.

Static Pressure Regulating Dampers are barometric relief dampers used to bypass excess air pressure on zoned systems. Properly balancing and adjusting dampers based on the system’s airflow requirements is essential for maintaining consistent static pressure levels throughout the ductwork.

Measurement of Static Pressure

1. Manometers

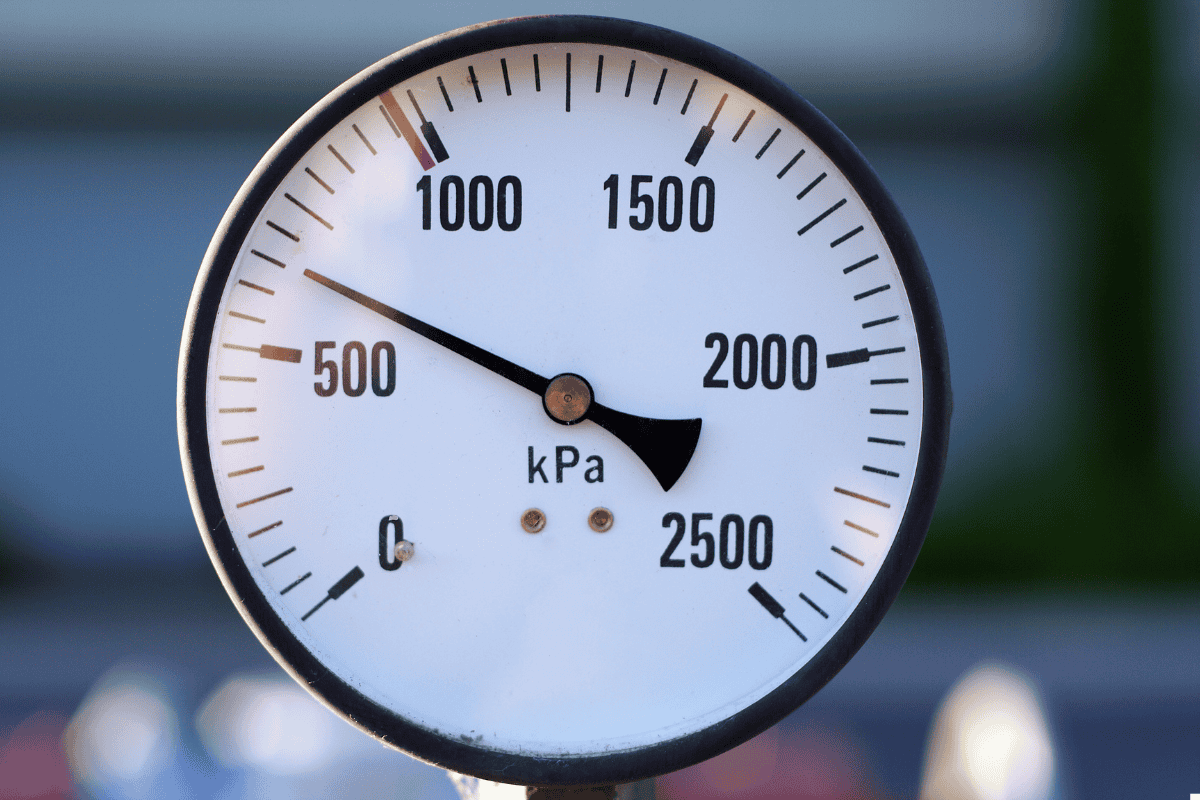

Manometers are simple, accurate instruments that consist of a U-shaped tube partially filled with a liquid, such as water or mercury.

To measure static pressure, one end of the manometer is connected to a point in the ductwork, while the other end is connected to a reference point. The pressure difference between these two points causes the liquid in the tube to rise or fall, indicating the static pressure reading.

While manometers provide reliable measurements, they may require manual calculations to convert the readings into preferred units, such as inches of water column or Pascals.

2. Digital Pressure Gauges

Digital pressure gauges offer a more user-friendly and precise method for measuring static pressure. These modern instruments provide real-time measurements and display the results on a digital screen, eliminating the need for manual calculations.

Digital pressure gauges often include additional features like data logging and wireless connectivity, allowing for remote monitoring of static pressure levels. This can be particularly useful for HVAC contractors and technicians who need to diagnose static pressure problems and optimize system performance.

How High and Low Static Pressure Affects HVAC

High Static Pressure

High static pressure in an HVAC system can have detrimental effects on its performance and efficiency. When static pressure is too high, it creates excessive resistance to airflow within the ductwork, restricting the quantity of air that can circulate through the system. This reduced airflow can lead to inadequate heating or cooling, as the conditioned air struggles to reach the desired areas of your home or building.

As a result of high pressure, your equipment, such as fans and motors, must work harder to overcome the increased resistance and maintain the necessary airflow. This additional strain on the system components can cause them to consume more energy, leading to higher utility bills and potentially shortening the lifespan of your equipment.

Moreover, increased pressure can cause uneven temperature distribution, leaving some rooms too hot or too cold, and reducing overall comfort levels.

Low Static Pressure

On the other hand, low pressure in an HVAC system can also negatively impact its performance. When static pressure is too low, it indicates that there is insufficient resistance to airflow within the ductwork. This can be caused by factors such as oversized ducts, leaks in the ductwork, or an undersized HVAC unit.

Low pressure can result in an inadequate amount of air passing over the heat exchanger, which can lead to overheating and potential damage to the system. Reduced static pressure can also cause your system to struggle to meet the desired temperature setpoints, resulting in longer run times and reduced energy efficiency.

Insufficient airflow due to low pressure can also contribute to poor quality of air, as the system may not be able to effectively circulate and filter the air within your home or building. This can lead to an accumulation of contaminants, such as dust, allergens, and other particulates, which can aggravate respiratory issues and cause discomfort for occupants.

How to Balance Static Pressure in HVAC Units

1. Static Pressure Testing and Analysis

Static pressure testing and analysis is a crucial step in balancing the static pressure in your air conditioning system. This process involves using specialized equipment, such as manometers or digital pressure gauges, to measure the static pressure at various points within the ductwork. By comparing these readings to the manufacturer’s specifications, technicians can identify areas where the static pressure is too high or too low.

2. Adjusting Dampers

Source: Angi

Dampers are mechanical devices installed within the ductwork that control the flow of air to different areas of your home or building. By adjusting these dampers, technicians can regulate the amount of air supplied to specific rooms or zones, helping to balance the static pressure throughout the system.

Adjusting dampers is a delicate process that requires a thorough understanding of the system and the principles of airflow. Homeowners should not attempt to adjust dampers themselves, as improper adjustments can lead to further imbalances and potentially damage the system.

3. Resizing Air Ducts

In some cases, the existing ductwork in your home or building may be improperly sized, contributing to static pressure imbalances. Ducts that are too small can create excessive resistance to airflow, leading to high static pressure, while oversized ducts can result in reduced pressure and inefficient air distribution.

Due to the complexity of this task and the potential impact on your system’s performance, resizing ducts should only be performed by experienced HVAC professionals.

4. Upgrading Equipment

In some situations, chronic static pressure issues may be caused by outdated or inefficient HVAC equipment. Older fans or air handlers may struggle to maintain the proper airflow and pressure levels, leading to imbalances throughout the system.

While upgrading equipment can be a significant investment, it can also provide long-term benefits in terms of energy savings, improved comfort, and reduced maintenance costs.

Struggling With Static Pressure Problems? Call HVAC Angel

At HVAC Angel, we understand the critical role that static pressure plays in the performance and efficiency of your system.

Our team of certified technicians has years of experience in diagnosing and resolving static pressure issues in both residential and commercial settings. We use state-of-the-art equipment, such as digital manometers and flow hoods, to accurately measure static pressure levels throughout your duct system. This allows us to pinpoint problem areas and develop targeted solutions to improve airflow and optimize your system’s performance.

Don’t let static pressure issues compromise the comfort and efficiency of your home or business. Trust the experts at HVAC Angel to provide the best HVAC service and solutions for balancing static pressure. Contact us today to schedule a consultation and experience the difference that our expertise can make in your system’s performance.

Frequently Asked Questions

1. How often should static pressure be monitored?

Static pressure should be monitored annually or whenever you notice issues like reduced airflow, uneven heating or cooling, or increased energy bills. Regular monitoring helps identify problems early and maintains optimal system performance.

2. Can I measure static pressure myself, or do I need a professional?

While it is possible to purchase static pressure measurement tools, it is recommended to have a professional HVAC technician perform this task. They have the expertise to accurately interpret the readings and make appropriate adjustments to balance your system.

3. How does duct design affect static pressure?

Duct design significantly impacts static pressure. Properly sized and configured ducts with smooth transitions and minimal turns help maintain optimal airflow and pressure.

4. Can static pressure affect indoor air quality?

Yes, static pressure imbalances can affect quality of air. High pressure can reduce airflow, limiting the system’s ability to filter and circulate air effectively. This can lead to an accumulation of contaminants and pollutants.

![9 Reasons That Causes an AC Unit to Freeze Up: [Troubleshooting Guide]](https://hvacangel.com/wp-content/uploads/2024/05/what-causes-a-ac-unit-to-freeze-up-1024x683.png)