An Energy Recovery Ventilator (ERV) is an important component of an HVAC system that helps maintain healthy indoor air quality while improving energy efficiency. The primary function of an ERV in HVAC is to exchange stale, moisture-laden indoor air with fresh, preconditioned outdoor air.

This process is achieved by transferring heat and humidity between the two airstreams, minimizing the load on your heating and cooling systems.

In this article, we’ll explore the world of ERVs and learn about their inner workings. By understanding their importance in your HVAC system, you’ll be better equipped to make informed decisions about your home’s ventilation needs.

Contents

What Does an ERV Do In HVAC?

Heat Exchange

The primary task of an ERV is to transfer heat between the incoming fresh air and the outgoing stale air. During winter, when you heat your home, the ERV captures heat from the warm indoor air before it’s exhausted outside. This recovered heat is then used to warm up the cold incoming air, reducing the workload on your heating system.

In summer, the process is reversed. The ERV transfers heat from the warm outside air to the cooler indoor air being exhausted. This precools the incoming air, easing the burden on your air conditioning system.

Moisture Exchange

In addition to heat transfer, ERVs also help manage humidity levels. If you live in a humid climate, excess moisture in the incoming air can make your home feel stuffy and uncomfortable. An ERV helps alleviate this issue by removing moisture from the incoming air before it enters your living space.

Conversely, in dry climates, ERVs can add moisture to the incoming air to prevent your indoor air from becoming too dry. This moisture transfer helps maintain a balanced and healthy humidity level in your home.

Types of Energy Recovery Ventilator Systems

1. Fixed Plate Heat Exchangers

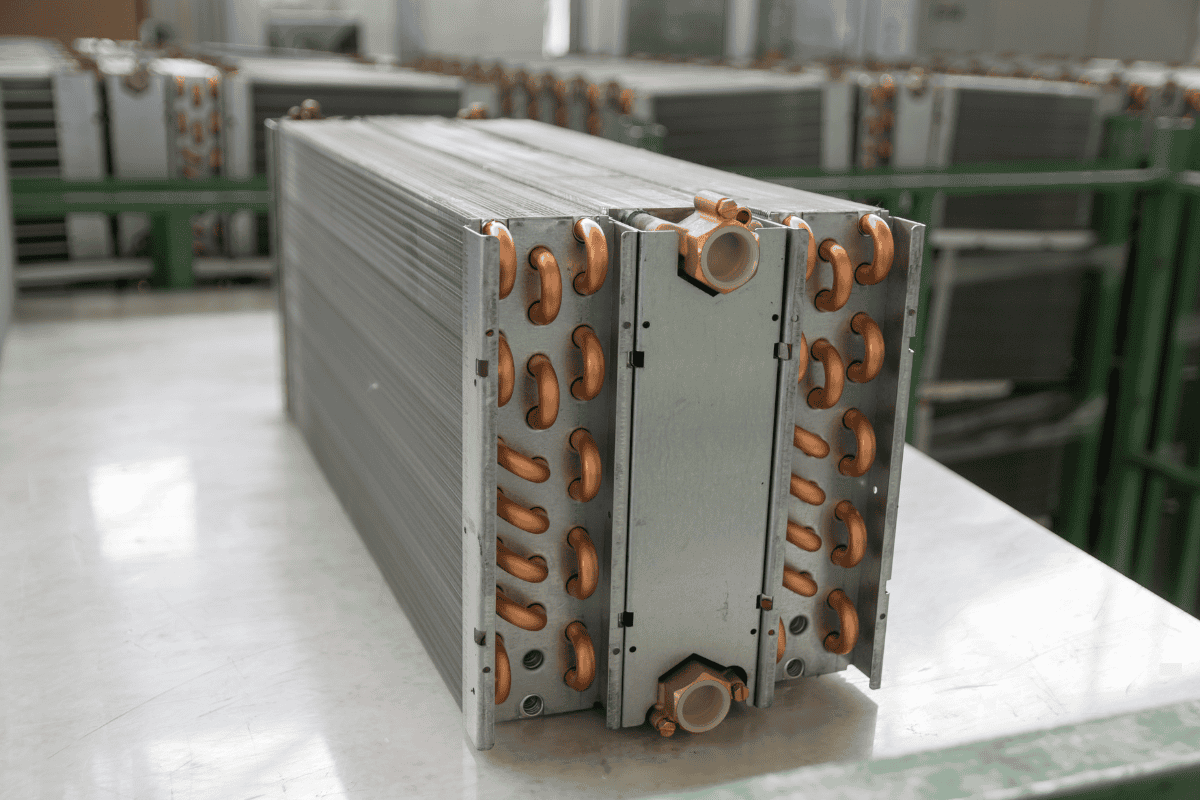

Fixed plate heat exchangers consist of a series of thin, stationary plates arranged in parallel, creating separate pathways for incoming and outgoing air. As the two airstreams pass through these plates, heat and moisture are transferred between them without the streams mixing directly.

The specialty of this type of ERV is its simple design, lack of moving parts, and low maintenance requirements, making it a reliable choice for many ventilation systems.

2. Rotary Heat Exchangers

Rotary heat exchangers comprise a rotating wheel or cylinder made of a heat-absorbing material. This wheel rotates between the incoming and outgoing air streams, transmitting heat and moisture as it spins.

The specialty of rotary heat exchangers lies in their high efficiency and effectiveness in both heat and moisture recovery, making them suitable for larger HVAC systems in residential or commercial settings.

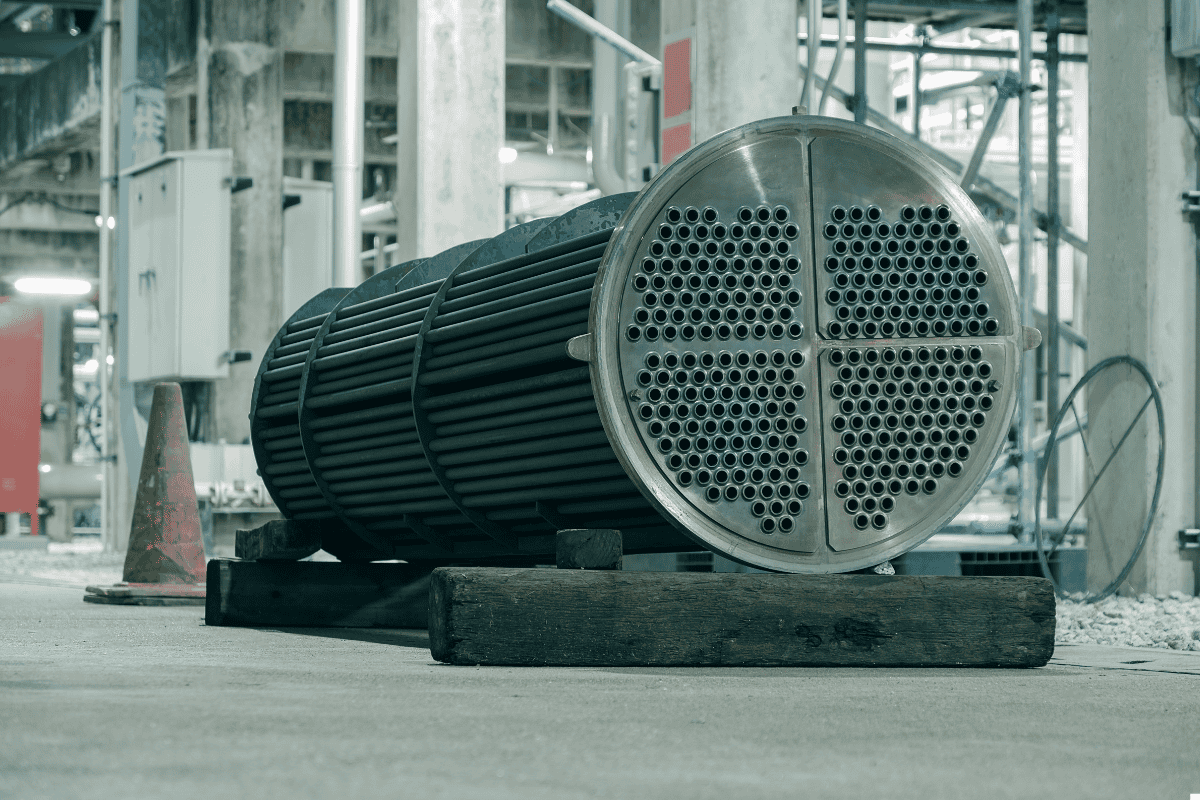

3. Heat Pipe Heat Exchangers

Heat pipe heat exchangers utilize sealed pipes filled with a refrigerant or other heat transfer fluid. In this system, heat is transferred from the warm, outgoing air to the fluid in the pipes, causing it to evaporate. The evaporated fluid then moves to the cooler, incoming air side, where it condenses and releases the heat.

The specialty of heat pipe heat exchangers is their high reliability and effective heat transfer without the need for moving parts, providing a long-lasting and efficient ventilation system.

4. Enthalpy Wheels

Enthalpy wheels feature a rotating wheel made of a material that can absorb both heat and moisture. As the wheel rotates between the incoming and outgoing air streams, it transfers both heat and moisture, enhancing humidity control.

The specialty of enthalpy wheels lies in their excellent heat and moisture recovery capabilities, high efficiency, and effectiveness in maintaining optimal indoor humidity levels. This system is particularly beneficial in areas with high humidity or in buildings with strict humidity control requirements.

ERVs vs. HRV System (Heat Recovery Ventilator)

Benefits of Energy Recovery Ventilation Systems

1. Energy Efficiency

ERV HVAC systems recover heat and moisture from the exhaust air, transferring it to the incoming fresh air. According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), air-to-air erv can recover energy from exhaust airstreams, reducing the energy needed to condition outdoor air by up to 80%.

By preconditioning the incoming air, they reduce the workload on heating and cooling systems, resulting in lower energy consumption and reduced utility bills. This leads to significant energy savings and improved HVAC efficiency in residential or commercial buildings.

2. Improved Indoor Air Quality

ERVs provide a continuous supply of fresh outdoor air, diluting indoor pollutants, allergens, and odors. The system filters incoming air to remove dust, pollen, and other particulates, maintaining cleaner air inside the building.

By maintaining proper ventilation and introducing filtered air from outside, these help keep indoor air quality at good levels. This is particularly important in modern, tightly-sealed buildings where natural ventilation may be limited.

3. Humidity Control

ERVs help maintain optimal indoor humidity levels by transferring moisture between the incoming and outgoing air streams. In humid climates, they remove excess moisture from the incoming air, preventing indoor humidity levels from becoming too high.

The Environmental Protection Agency (EPA) states that indoor humidity levels above 60% can promote mold growth and increase allergen levels, impacting quality of indoor air.

4. Reduced Heating and Cooling Loads

By transferring heat and moisture, ERVs precondition the incoming air, reducing the load on the heating and cooling systems. The system takes heat energy from the stale outgoing air and transfers it to the fresh incoming air, depending on the season. This process reduces the amount of energy needed to condition the air entering the building.

Disadvantages of ERV System

1. Higher Initial Cost

ERVs tend to be more expensive than HRVs due to their more complex design and additional components for moisture transfer. The initial investment can be higher, which might be a concern for budget-conscious homeowners. An ERV system may save you money in the long run, but the initial installation may cost $2,000 or more.

This higher upfront cost can be a barrier for some homeowners looking to improve their home’s ventilation and energy efficiency.

2. Maintenance Requirements

The presence of moisture transfer components means ERVs require more regular maintenance for optimal performance and prevent issues like mold growth. Filters and heat exchanger cores need to be checked and cleaned every 3 months or replaced periodically if they are reusable.

This added maintenance can be a burden for homeowners and may lead to increased costs over time if not performed regularly.

3. Complexity

The dual function of transferring both heat and moisture makes ERVs more complex systems compared to other ventilation options. Installation and integration with existing HVAC systems can be more challenging and may require professional expertise.

This complexity can lead to higher installation costs and potential difficulties in finding qualified technicians for maintenance and repairs.

4. Operational Challenges

In extremely cold climates, moisture recovery can lead to condensation and potential freezing issues within the ERV system. Safeguards or defrost cycles may be needed to prevent freezing, adding to the complexity and maintenance needs.

These operational challenges can reduce the overall efficiency of the system and may require additional energy consumption to manage.

Need Help With Your ERV? Contact HVAC Angel

At HVAC Angel, we are dedicated to providing top-notch services to homeowners and businesses alike. When it comes to ERVs, our team of skilled technicians has the knowledge and experience of installing an erv and handling any issue you may encounter.

We understand that even with regular maintenance and care, these systems can sometimes experience problems that require professional attention. That’s where we come in. Our technicians are equipped with state-of-the-art tools and equipment to diagnose and resolve any ERV-related issues quickly and efficiently.

If you’re experiencing issues with your system or simply need expert advice on how to optimize its performance, don’t hesitate to contact HVAC Angel. Our friendly and knowledgeable staff is ready to assist you with all your needs.

Trust us to provide the highest quality service and support. Call us today to schedule your appointment and experience the HVAC Angel difference!

Frequently Asked Questions

1. What is the difference between ERV and HVAC?

An ERV is a specific component of an HVAC (Heating, Ventilation, and Air Conditioning) system. While HVAC refers to the overall system that regulates indoor temperature and air quality.

2. Can ERV run continuously?

Yes, ERVs can run continuously to provide a constant supply of fresh air and maintain good air quality. However, some ERV systems may be configured to run intermittently based on specific ventilation requirements or to save energy during periods of low occupancy.

3. Is an ERV required?

While ERVs are not always legally required, they are highly recommended for maintaining healthy air quality and energy efficiency. Building codes and green building standards may dictate the need for ERVs in certain situations, such as in tightly sealed buildings or in areas with specific climatic conditions.

4. How many CFM do I need for an ERV?

The required CFM (Cubic Feet per Minute) for an ERV depends on various factors, including the size of the space, occupancy levels, and ventilation needs. A general rule of thumb is to provide 15-20 CFM per person or 0.35 air changes per hour (ACH) for residential applications.

![9 Reasons That Causes an AC Unit to Freeze Up: [Troubleshooting Guide]](https://hvacangel.com/wp-content/uploads/2024/05/what-causes-a-ac-unit-to-freeze-up-1024x683.png)