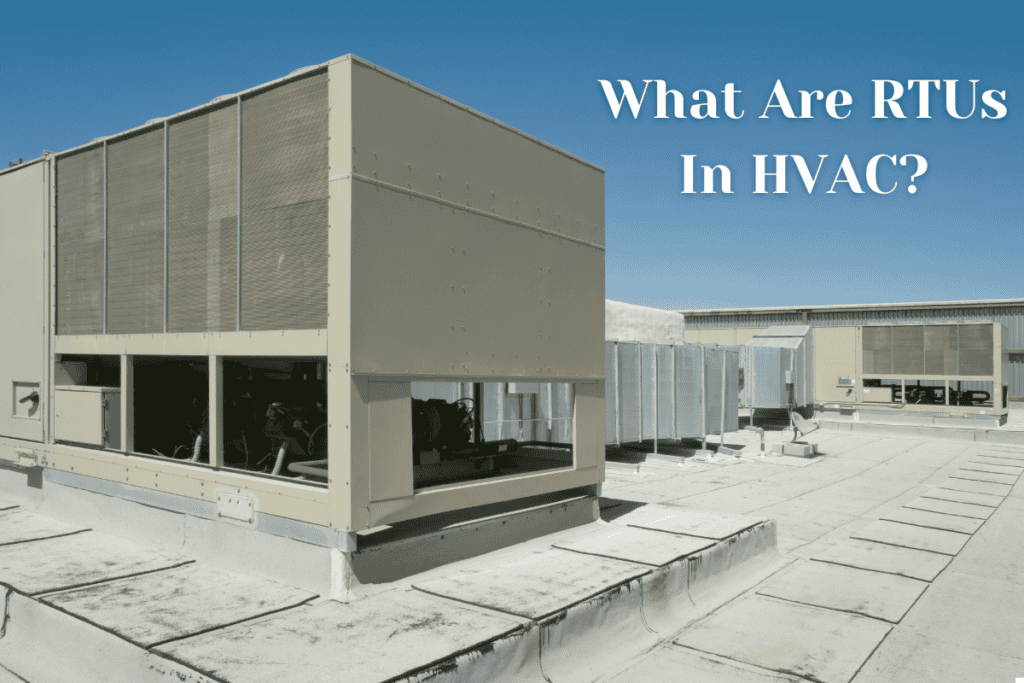

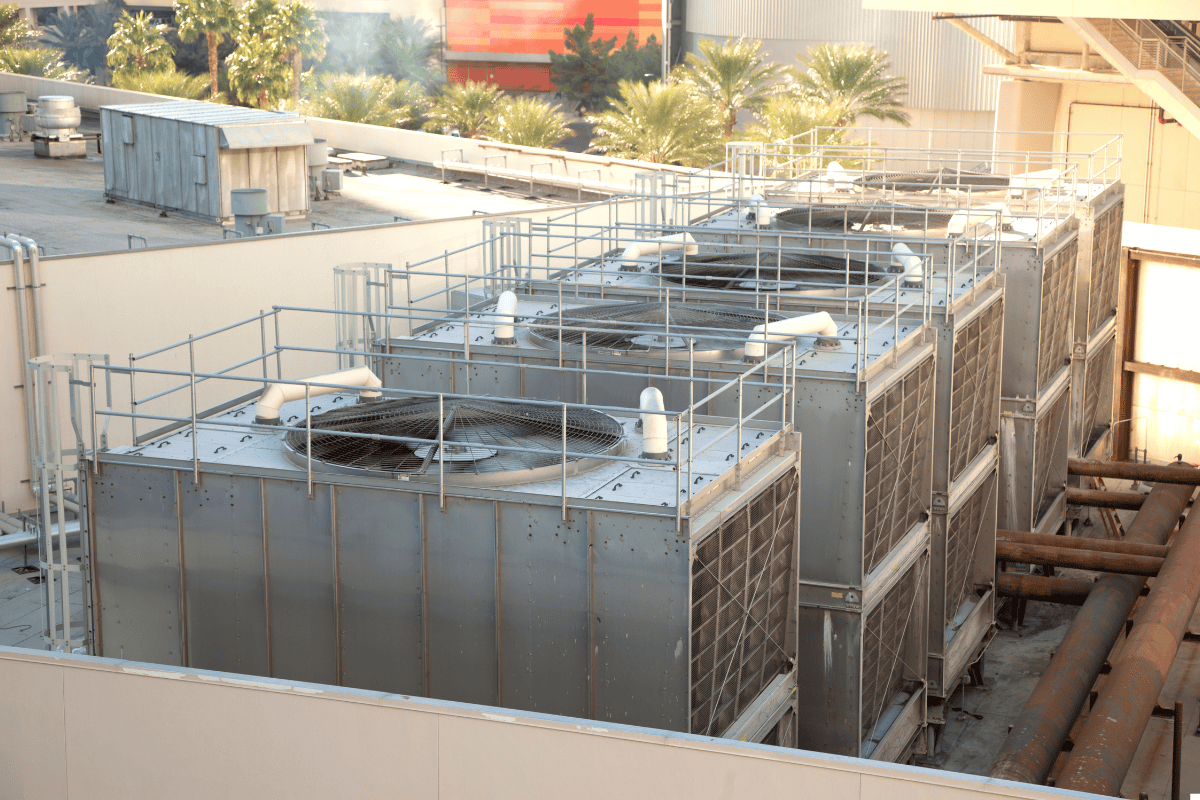

Rooftop units, commonly known as RTUs, are designed to provide heating, ventilation, and air conditioning. These units are typically installed on the rooftops of structures, serving as a centralized solution for regulating indoor climate conditions, including temperature control and air quality management.

RTUs are comprehensive systems that combine all the essential components necessary for heating, cooling, and ventilating a building into a single, integrated package. These components work together seamlessly for optimal indoor comfort and air quality, making RTUs a popular choice for commercial spaces.

In this comprehensive guide, you’ll get your RTU, rooftop unit explained. We’ll explore their components and how they function, different types of RTUs available in the market, and the advantages they offer over traditional systems.

We’ll provide insights into the installation process, maintenance requirements, and energy efficiency considerations to help you make informed decisions about these versatile HVAC solutions.

Contents

Components of an RTU In HVAC System

1. Air Handling Unit (AHU)

The Air Handling Unit (AHU) plays a vital role in circulating conditioned air throughout the building and maintaining optimal indoor air quality. This component is responsible for drawing in air from the indoor space, filtering it, and then distributing it back into the designated areas through a network of ductwork connections.

At the heart of the AHU lies a powerful fan or blower system that generates the airflow necessary for effective air circulation. This fan draws in air from indoors and pushes it through a series of filters designed to remove airborne particles, dust, and other contaminants, ensuring the air remains clean and healthy.

The filtered air then passes through the heating and cooling components of the RTU HVAC system.

2. Compressor

The compressor is a critical component in an RTU system, playing a central role in the cooling cycle. Its primary function is to compress the refrigerant, increasing its pressure and temperature, which enables effective heat transfer necessary for cooling the indoor space.

It operates by converting low-pressure refrigerant into a high-pressure, high-temperature gas. This compressed refrigerant then flows through the condenser coil, where it releases heat to the outside air, allowing it to condense back into a liquid state. The liquid refrigerant then passes through an expansion device, which lowers its pressure and temperature, enabling it to absorb heat from the indoor air as it circulates through the evaporator coil.

According to Climate Care, an AC compressor in a properly maintained system can typically last about 12-15 years. However, its lifespan may vary depending on factors such as usage patterns, environmental conditions, and regular maintenance practices.

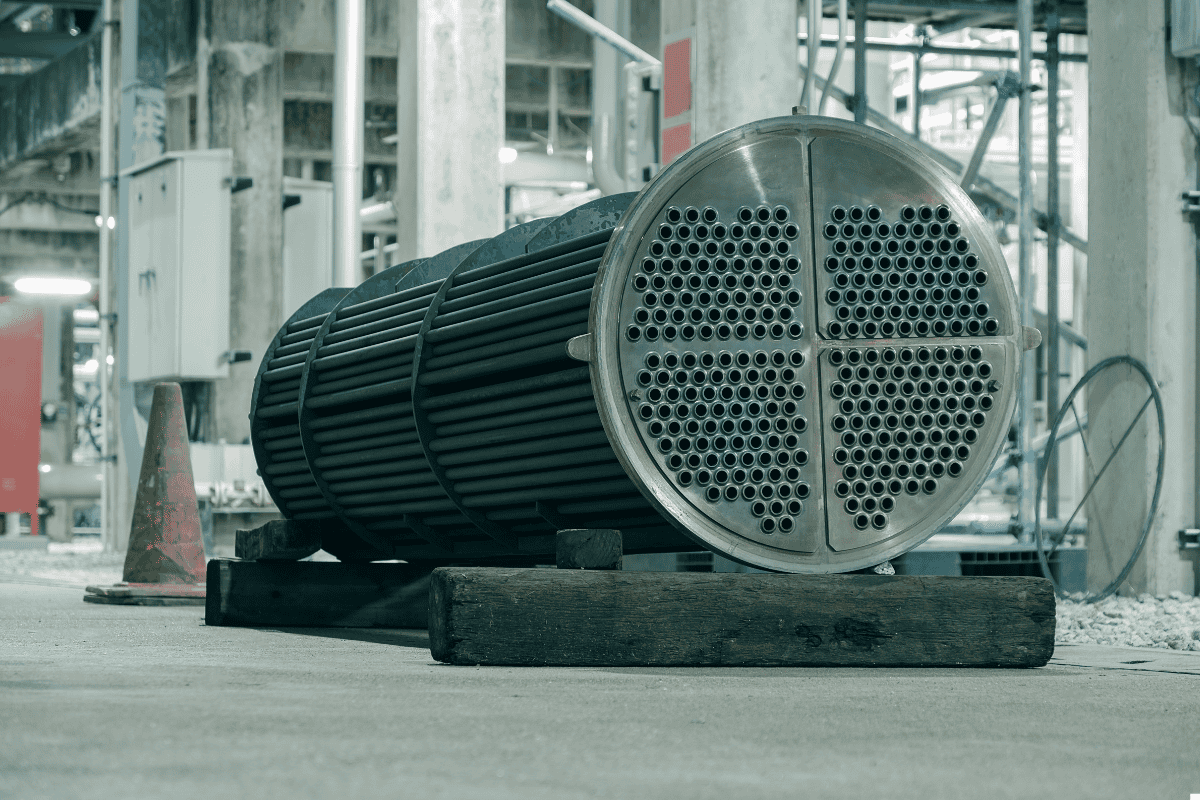

3. Heat Exchanger

The heat exchanger in RTU HVAC unit is responsible for transferring heat between the air and the refrigerant without allowing them to mix. This component facilitates efficient thermal energy transfer, which is essential for both heating and cooling processes.

The heat exchanger consists of two main types: evaporators and condensers. The evaporator coil acts as a heat absorber, taking in heat from the return air inside the building, allowing the refrigerant to absorb this heat and cool the air. On the other hand, the condenser coil releases the absorbed heat from the refrigerant to the outside air, enabling the refrigerant to cool down and continue the cycle.

4. Condenser

The condenser is responsible for releasing the heat absorbed from the indoor air to the outside environment.

The condenser comprises two main parts: the condenser coil and a fan, both important for the RTU unit functionality. The condenser coil is a series of tubing that carries the high-pressure refrigerant gas. As the refrigerant passes through the coil, the fan draws in outdoor air and blows it across the coil, facilitating heat dissipation from the refrigerant to the outside air. This process causes the high-pressure refrigerant gas to condense into a liquid, releasing the heat it absorbed from the indoor air.

By releasing the absorbed heat to the outdoor environment, the condenser allows the refrigerant to complete the cooling cycle and continue absorbing heat from the indoor air. An AC condenser in a well-maintained system can last approximately 15 years.

5. Evaporator Coil

The evaporator coil is another component of the RTU, responsible for absorbing heat from the indoor air, effectively cooling it as the air passes over the coil.

The evaporator coil operates by allowing low-pressure refrigerant to absorb heat from the indoor air. As the warm indoor air passes over the coil, the refrigerant inside the coil absorbs the heat, causing it to evaporate from a liquid to a gaseous state. This process cools the air, which is then circulated back into the indoor space through the ductwork system.

The evaporator coil is typically located inside the air handling unit or the indoor section of the RTU. This strategic placement provides that the indoor air passes directly over the coil, allowing for efficient heat absorption and cooling.

By absorbing heat from the indoor air, the evaporator coil plays a vital role in maintaining a comfortable and consistent temperature inside the building.

6. Control Panel

The control panel is a vital component of a rooftop unit (RTU), serving as the brain that regulates and optimizes the system’s performance. It houses the controls for temperature settings, fan speeds, and operation modes, maintaining user comfort and energy efficiency.

The control panel typically includes several components, such as circuit boards, sensors, and user interfaces. The circuit boards contain the electronic controls and programming that govern the RTU’s operations. Sensors are integrated into the system to monitor various parameters, such as temperature, humidity, and airflow, providing feedback to the control panel for appropriate adjustments.

One of the primary functions of the control panel is to regulate temperature settings and fan speeds based on user preferences or pre-programmed settings. Users can input their desired temperature and fan speed through the user interface, and the control panel will automatically adjust the RTU’s components.

What Are The Types of Rooftop Units

1. Packaged Units

Packaged RTUs, also known as packaged units, are self-contained units that combine the compressor, condenser, evaporator, and air handler in a single enclosure. These units are often used in commercial applications, offering a compact and efficient solution. They are ideal for small to medium-sized commercial spaces, such as retail stores, offices, and light industrial facilities, providing a cost-effective way to deliver conditioned air.

2. Split Systems

Split systems, as the name suggests, separate the indoor and outdoor components of the RTU. The indoor unit consists of the evaporator and air handler, while the outdoor unit houses the compressor and condenser. This separation allows for more flexibility in the design and installation, making split systems suitable for larger commercial and industrial applications. Split air conditioning systems are Energy Star certified with high SEER ratings.

3. Dedicated Outdoor Air Systems (DOAS)

Dedicated Outdoor Air Systems, or DOAS, are designed to bring in fresh air from the outside directly into the building. These systems are often used in combination with other HVAC equipment, providing a dedicated source of outdoor air to improve indoor air quality and ventilation. DOAS units are particularly useful in environments with high occupancy levels, such as schools, restaurants, and office buildings, where maintaining good indoor air quality is crucial.

4. Energy-Efficient RTUs

Many RTUs are designed with energy efficiency in mind, incorporating features like high-efficiency compressors, low-noise fans, and advanced filtration systems. These energy-efficient RTUs can significantly reduce energy consumption, resulting in lower utility bills and a more environmentally friendly operation.

5. Customizable Solutions

RTUs are also available in customizable solutions, allowing for tailored configurations to meet specific needs. For example, you can choose from a variety of tonnages, refrigerants, and filter ratings to optimize the system for your particular requirements.

How Rooftop Unit Work

Basic Operational Principles

RTUs are self-contained HVAC systems that provide heating, cooling, and ventilation from a single unit typically installed on the roof of a building. They are designed to be efficient and compact, making them ideal for commercial applications. RTUs condition the air by either heating or cooling it and then distributing the conditioned air throughout the building via a ductwork system.

Cooling Cycle

The cooling cycle begins with the compressor, which compresses the refrigerant, raising its temperature and pressure. The hot, high-pressure refrigerant then moves to the condenser coil where it releases heat to the outside air and condenses into a liquid. The liquid refrigerant then travels to the evaporator coil inside the air handling unit.

As it passes through the evaporator coil, it absorbs heat from the indoor air, evaporating into a gas. This process cools the air, which is then circulated throughout the building. The refrigerant, now a low-pressure gas, returns to the compressor to begin the cycle again.

Heating Cycle

In heating mode, the RTU can use various methods to generate heat, such as electric heating elements, a gas furnace, or a heat pump. This makes an RTU versatile in its heating capabilities. In a heat pump, the cycle is reversed: the refrigerant absorbs heat from the outside air and releases it inside the building.

The heated refrigerant passes through the heat exchanger, transferring heat to the indoor air. The warmed air is then distributed through the ductwork to heat the building. The system is designed to efficiently transfer and distribute heat, maintaining consistent indoor temperatures.

Ventilation Process

RTUs bring in fresh outdoor air for good indoor air quality. This air is filtered and conditioned before being mixed with the return air from the building. The ventilation process helps to remove indoor air pollutants, manage humidity levels, and provide a constant supply of fresh air.

Some RTUs include energy recovery ventilators (ERVs) that reclaim energy from the exhaust air to precondition the incoming fresh air, enhancing energy efficiency.

Advantages of Using RTU HVAC

1. Space-Saving Design

RTUs are installed on the roof of a building, saving valuable indoor space for other uses. This design is especially beneficial for commercial buildings with limited floor space. Additionally, the all-in-one design of RTUs consolidates multiple HVAC components into a single, compact unit, further reducing the space required inside the building.

2. Ease of Installation and Maintenance

Since RTUs are self-contained units, they require less complex installation procedures compared to split systems. This can reduce installation time and costs. Maintenance tasks are also simplified as all components are housed in one place, making it easier for technicians to perform regular upkeep and repairs.

3. Energy Efficiency

RTUs are designed to operate efficiently by optimizing the interaction between all components. This integration often results in lower energy consumption compared to separate systems. Many packaged rooftop units come with energy-efficient features such as variable speed fans, economizers, and advanced controls that help reduce energy usage and costs.

4. Flexibility in Design and Application

RTUs can be customized to meet the specific heating, cooling, and ventilation needs of different commercial buildings. They can be configured with various capacities and options to suit a wide range of applications.

The modular nature of RTUs allows for easy scaling, making them suitable for both small and large commercial spaces. Additional units can be added as needed to accommodate building expansions or increased demand.

5. Reduced Noise Levels

Placing the unit on the roof helps to minimize indoor noise, as the loudest components, such as the compressor and condenser fan, are located outside the building envelope. Many RTUs are designed with noise-reducing features, such as insulated panels and vibration dampeners, to further decrease operational noise and enhance occupant comfort inside the building.

Contact HVAC Angel For Your AC Needs

At HVAC Angel, we understand the importance of professional HVAC services. We, provide expert solutions for all your heating, ventilation, air conditioning, and refrigeration needs.

Our team of certified technicians has extensive knowledge and experience in various HVAC systems, including rooftop units (RTUs), split systems, and water-cooled chillers. We offer comprehensive services, from installation and repair to maintenance and energy audits.

Keeping your RTU operating at peak efficiency is important for maintaining a comfortable environment, controlling energy costs, and prolonging equipment life. Regular maintenance helps prevent costly breakdowns, improves air quality, and maintains code compliance.

Frequently Asked Questions

1. Is AHU the same as RTU?

No, AHU (Air Handling Unit) and RTU (Rooftop Unit) are not the same. An AHU is a component within an RTU that circulates and conditions the air.

2. How do RTUs contribute to indoor air quality?

RTUs contribute to indoor air quality in several ways. They bring in fresh outdoor air, which is filtered and conditioned before being circulated indoors. This helps remove pollutants and maintain proper ventilation. RTUs often include energy recovery ventilators (ERVs) that reclaim energy from exhaust air to precondition the incoming fresh air, improving energy efficiency while maintaining indoor air quality.

3. In what types of buildings are RTUs commonly used?

RTUs are commonly used in various commercial and industrial buildings due to their versatility and space-saving design. Some common applications include office buildings, retail spaces, restaurants, schools, healthcare facilities, and low-rise commercial structures. They are particularly suitable for buildings up to 10 stories tall, where their rooftop installation is convenient and efficient.

![9 Reasons That Causes an AC Unit to Freeze Up: [Troubleshooting Guide]](https://hvacangel.com/wp-content/uploads/2024/05/what-causes-a-ac-unit-to-freeze-up-1024x683.png)